Flexible plastic sheets are a game-changer when you need something tougher than paper but don't want the rigidity of hard plastic. Essentially, they are thin, durable materials made from polymer compounds that blend the printability of premium paper with the resilience of plastic. This makes them perfect for projects that need to last and stand up to a bit of rough and tumble.

Bridging the Gap Between Paper and Rigid Plastic

Think of flexible plastic sheets as an 'industrial-grade paper'. Where a standard paper or cardboard sign would tear, get soggy, or stain at the first sign of trouble, these sheets hold their own. They are specifically engineered to solve those all-too-common business problems by offering a tough, printable surface that thrives in more demanding environments.

But they aren't completely stiff, and that’s the magic. Unlike thick, unbending acrylic or foamex, they have a certain amount of give. This unique balance means they can be bent, rolled, or even lightly folded without snapping, giving you a fantastic mix of durability and adaptability for all sorts of creative and practical uses.

What’s Their Core Purpose for Businesses?

At their heart, these materials provide a robust way to communicate your message or brand where other materials just can't cut it. Their built-in resistance to moisture, tearing, and fading makes them a far superior choice for a huge range of commercial applications. The result? Printed materials that not only look sharp but also last significantly longer, which means less money spent on replacements and a consistently professional look.

This durability is non-negotiable for items that are handled a lot or left exposed to the elements.

- Waterproof Qualities: Ideal for menus in a busy cafe or outdoor signage that has to endure the classic British weather.

- Tear Resistance: Ensures things like event passes, workshop tags, or durable instruction manuals stay in one piece.

- Wipe-Clean Surface: An absolute must for maintaining hygiene in hospitality, healthcare, or school settings.

- Excellent Print Fidelity: These advanced surfaces allow for stunningly vibrant, high-resolution graphics that keep your brand colours looking spot-on.

At its core, a flexible plastic sheet is a problem-solver. It replaces flimsy, single-use paper with a long-lasting, professional-grade alternative that protects your investment and enhances your brand's presentation.

How Do They Differ from Other Materials?

It's helpful to know exactly where these sheets fit in the printing world. While we offer super-sturdy solutions for more permanent installations with our rigid board printing services, flexible sheets serve a different need. They are your go-to when you need resilience combined with that crucial bit of pliability.

You might also come across materials like architectural films, which are generally used for surfacing existing objects. Flexible sheets, however, are typically designed as standalone products. If you're curious about surfacing materials, this article explains what architectural film is and how to use it.

From weather-resistant outdoor banners and high-quality stickers to innovative packaging, these sheets provide a dependable foundation for your projects. They neatly bridge the gap between temporary paper printouts and permanent fixtures, offering a powerful, adaptable solution for countless jobs. This guide will walk you through the different types, finishes, and uses to help you pick the perfect one.

Comparing The Most Common Plastic Sheet Materials

Picking the right material for your printed project is a bit like choosing the right tool for a job. You wouldn't use a sledgehammer to hang a picture, right? In the same way, not all flexible plastic sheets are created equal. Each type comes with its own unique strengths, weaknesses, and ideal uses, and understanding the differences is key to making sure your final product not only looks brilliant but performs perfectly.

Let's break down the three main players you'll come across here at The Print Warehouse Ltd: Polyvinyl Chloride (PVC), Polyethylene Terephthalate (PET), and Polypropylene (PP). We’ll skip the dense chemistry lesson and get straight to what matters for your business—how it looks, how it lasts, and where it works best.

PVC: The Outdoor Workhorse

Think of Polyvinyl Chloride (PVC) as the rugged, all-weather champion of the plastic sheet world. It's incredibly durable, flame-retardant, and holds its own against UV light, moisture, and general wear and tear. This powerful combination makes it the go-to material for anything that needs to survive the great outdoors or withstand constant handling.

Its natural strength and pliability mean it can be turned into a huge range of products. When you need a sign that won’t fade after a month in the sun or a banner that can handle a surprise downpour, PVC is almost always the answer.

- Best for: Outdoor banners, durable signage, industrial tags, and weatherproof covers.

- Key Advantage: Unmatched durability and weather resistance, making it perfect for long-term outdoor use.

Take our hugely popular printed banners, for example. They’re made from high-quality PVC for this very reason. They're built to get your message seen, rain or shine, making them a reliable investment for any promotion. You can see what’s possible by checking out our PVC banners and discover how they could work for you.

PET: The Clear and Premium Choice

Next up is Polyethylene Terephthalate (PET), a material loved for its exceptional clarity and strength. If you've ever bought a bottle of water, you've handled PET. In sheet form, it gives a crystal-clear, glossy finish that makes colours pop and lends projects a high-end, premium feel.

Crucially, PET is often food-safe, which makes it a top contender for packaging where the product needs to be seen and kept safe. It’s also highly recyclable—often marked with the number 1 recycling symbol—which is a huge plus for environmentally conscious brands.

While PVC is the tough exterior defender, PET is the polished interior specialist. It excels where visual appeal and clarity are everything, offering a clean, professional look that elevates your product.

This material strikes a fantastic balance between being lightweight and incredibly tough. It resists impacts well without easily cracking, providing reliable protection. When weighing up your options, it's also helpful to look at the bigger picture, like in this guide on choosing your best sign board material for a wider range of uses.

PP: The Lightweight and Versatile Option

Finally, let’s talk about Polypropylene (PP). Imagine a material that’s incredibly light yet surprisingly rigid and resistant to chemicals, heat, and fatigue. That’s polypropylene in a nutshell. It’s the stuff used in everything from car parts to those reusable food containers you have in the cupboard.

One of PP's standout features is its "living hinge" capability—it can be flexed over and over again without breaking. This makes it perfect for things like ring binders or folders that get opened and closed thousands of times. It’s also highly resistant to most chemicals and solvents, a vital property for industrial tags or medical trays.

- Best for: Reusable packaging, stationery folders, medical trays, and chemical-resistant labels.

- Key Advantage: It is extremely lightweight, chemically resistant, and has excellent fatigue resistance.

Because it’s less dense than other plastics, you get more material for the same weight, which can make it a very cost-effective choice for large-volume projects.

Flexible Plastic Sheet Material Comparison

To help you see the differences at a glance, we've put together a simple comparison table. This should make it easier to line up your project's needs with the right material's strengths.

| Material | Key Properties | Best For | Considerations |

|---|---|---|---|

| PVC | Extremely durable, weather-resistant, flame-retardant, UV-resistant. | Outdoor banners, long-term signage, heavy-duty applications. | Less eco-friendly than PET or PP. Heavier. |

| PET | Crystal-clear, high-gloss finish, strong, impact-resistant, often food-safe. | Premium packaging, point-of-sale displays, food containers. | Can be more expensive. Prone to scratching. |

| PP | Lightweight, chemically resistant, excellent fatigue resistance (living hinge). | Reusable packaging, folders, binders, industrial tags. | Lower clarity than PET. Can be harder to print on. |

Each material has its place, and the "best" one is simply the one that ticks all the boxes for your specific job.

Making The Right Decision For Your Project

To simplify your choice, think about the most important thing your project needs to do. Is it battling the elements outdoors? PVC is your strongest ally. Do you need pristine clarity for a food product or a premium display? PET is the clear winner. Or is your focus on a lightweight, reusable, and chemically resistant solution? Then Polypropylene is likely the perfect fit.

By matching the material’s core strengths to your project's demands, you set yourself up for a successful result every time.

Understanding Sheet Thickness and Finishes

Once you’ve picked a material like PVC or PET, the next step is to nail down the physical specs that give your product its final look and feel. The two big players here are the sheet's thickness and its surface finish. Getting these right is key to making sure the material works as intended while looking exactly how you envisioned.

Think of plastic sheet thickness like you would the weight of paper. With paper, we talk about grams per square metre (gsm) to describe its sturdiness. For plastics, we use microns (µm). A higher micron number means a thicker, more rigid sheet, whereas a lower one is thinner and more flexible.

For instance, a 200-micron sheet is quite thin and bendy, perfect for lightweight packaging inserts or disposable event passes. On the other hand, a beefy 450-micron sheet is much stiffer, making it a great choice for durable, wipe-clean menus or semi-rigid point-of-sale displays that need to stand on their own.

Sheet Formats: Rolls Versus Pre-Cut

Flexible plastic sheets generally come in two formats, each suited to different jobs.

- Rolls: These are your go-to for large-format printing. Think huge, eye-catching banners or long runs of custom-shaped stickers where you want to get the most out of your material and keep waste to a minimum.

- Pre-cut Sheets: For standard sizes like A4 menus, A5 flyers, or business cards, pre-cut sheets are far more efficient. They streamline production, making them ideal for consistent, repeatable print runs.

The choice really boils down to the scale and specifics of your project. For bespoke, large-scale graphics, rolls offer unmatched flexibility. For almost everything else, pre-cut sheets are a convenient and budget-friendly starting point.

The Impact of Surface Finishes

The finish on your plastic sheet makes a massive difference to its final appearance and how easy it is to read. It can make colours pop or give them a more subtle feel, and it plays a huge role in how your product handles light.

A gloss finish is like a fresh coat of varnish on a painting. It creates a highly reflective, shiny surface that makes colours look deeper and more vibrant. This makes it an excellent choice for promotional stickers, high-impact posters, or product packaging that needs to stand out on a crowded shelf. The smooth surface is also very easy to wipe clean.

On the other hand, a matt finish is non-reflective and has a soft, muted look. This is perfect for situations where readability is the top priority. It cuts down on glare from overhead lights or sunshine, making it the ideal choice for outdoor signage, information panels, and menus in brightly lit restaurants. Our guide to waterproof posters explores how the right finish can make all the difference in challenging environments.

Choosing a finish isn't just about looks; it's about function. A gloss finish shouts for attention with vibrant colour, while a matt finish makes sure your message gets read without any distracting reflections.

By carefully choosing the right thickness, format, and finish, you can ensure your printed plastics perform exactly as you need them to, delivering both durability and the perfect visual punch.

How to Print and Finish Your Plastic Sheets

Getting a design onto a non-porous surface like a flexible plastic sheet is a different ball game compared to printing on paper. Paper soaks up ink, but plastic requires specialised techniques to make sure your design is vibrant, sharp, and tough enough to last. The right printing and finishing methods are what turn a plain sheet into a professional, hard-wearing product.

At The Print Warehouse, we use the latest technology to get incredible results on these versatile materials. Let's look at the printing processes that make your designs pop and the finishing touches that take them from good to great.

Choosing the Best Printing Technology

Printing on plastic isn’t a one-size-fits-all job. The best method really comes down to the material itself, how complex your design is, and what you’ll be using the final product for. Two technologies, in particular, lead the pack for producing top-quality results on flexible plastics.

UV Printing – The Gold Standard for Durability

Imagine an ink that dries the very instant it’s hit with a special light. That’s the magic behind UV printing. In this process, we apply liquid ink to the plastic sheet and then immediately cure—or harden—it with intense ultraviolet (UV) light. This instant-drying method is a game-changer for a few key reasons:

- Exceptional Durability: The cured ink forms a tough, resilient layer on the surface that’s highly resistant to scratches, fading, and moisture. This makes it the perfect choice for outdoor signage or any product that will be handled a lot.

- Vibrant Colours: Because the ink doesn't have time to bleed or spread, the dots of colour stay incredibly crisp and vivid. The result is stunning, high-resolution graphics with brilliant colour.

- Material Versatility: UV printing works beautifully on a huge range of plastics, including PVC, PET, and Polypropylene, without needing any special coatings first.

Think of UV printing as creating a robust, almost-armoured layer of ink on the plastic's surface. This is why it’s our go-to method for products that need to look fantastic while standing up to the elements and daily use.

Screen Printing – For Bold and Simple Designs

Screen printing is a classic and powerful technique, especially when you need a large number of prints with a simpler design. It works by pushing ink through a stencilled mesh screen directly onto the plastic sheet. Each colour in the design gets its own screen, making it ideal for graphics with just a handful of colours.

This method is fantastic for producing bold, solid colours that really stand out. It’s a cost-effective solution for high-volume orders of items like branded folders or simple safety signs, delivering consistent quality every single time.

Essential Finishing Options

Printing is only half the story. Finishing is where we add the final touches that boost both the look and function of your flexible plastic sheets, turning them into polished, professional products ready for action.

Lamination – Protecting Your Investment

Lamination involves applying a thin, transparent plastic film over the printed surface. This adds a crucial layer of protection against scuffs, chemicals, and UV rays, which can dramatically extend the life of your product. It’s an essential step for items like restaurant menus that need to be wiped clean constantly or for posters in busy areas. For more ideas on creating durable prints, take a look at our guide to poster printing and see how lamination can boost longevity.

Die-Cutting – Creating Custom Shapes

Want a sticker shaped like your logo, or a product tag with a unique outline? That’s where die-cutting comes in. Using a custom-made die (a bit like a cookie cutter), we can cut the plastic sheets into almost any shape you can think of. This process gives you complete creative freedom, helping your products break away from standard rectangles and truly stand out from the crowd.

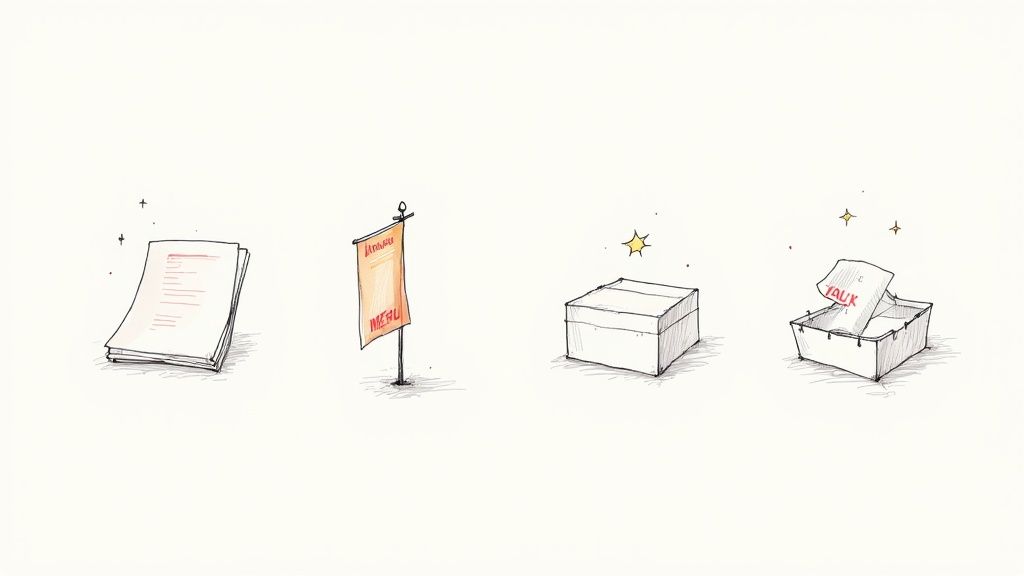

Creasing and Folding for 3D Applications

Many flexible plastics, especially Polypropylene, are perfect for creating items that need to be folded. By applying a crease—a precisely indented line—we create a clean fold that allows the sheet to be shaped into products like:

- Table Talkers: Sturdy, self-standing displays for restaurant tables or reception desks.

- Product Packaging: Custom boxes and sleeves that protect and show off your goods.

- Presentation Folders: Durable and reusable folders that make a professional impression.

These finishing touches are what tailor a versatile material to your specific needs, ensuring the final product isn’t just durable and well-printed, but also perfectly suited to its job.

Real-World Inspiration: What Can You Create with Flexible Plastic Sheets?

It’s one thing to talk about microns and finishes, but it’s seeing these materials in action that really gets the ideas flowing. Let’s step away from the technical specs and look at how businesses are using flexible plastic sheets to solve real-world problems with a touch of style and a whole lot of durability.

Each of these examples is a story of a challenge overcome. It’s about making a lasting impression, protecting a product, or simply making life easier.

From a bustling café to an outdoor festival, you’ll see how choosing the right material can make all the difference.

Resilient Menus for Busy Hospitality Venues

Picture a packed coffee shop on a Saturday morning. Coffee gets spilled, tables are wiped down constantly, and paper menus just don’t stand a chance. Within hours, they can look stained and dog-eared, which is never a good look for your brand. This is a classic problem that flexible plastic sheets solve perfectly.

By printing menus on a tough, waterproof plastic like 450-micron PVC with a matt finish, you get something that’s both elegant and practically indestructible. These menus can be wiped clean hundreds of times without the ink smudging or the material falling apart.

The result? A menu that looks brand new for months, not just for the first customer of the day. It’s a simple switch that cuts down on reprinting costs and ensures every customer gets a clean, professional menu.

For any hospitality business tired of shabby-looking menus, exploring durable, waterproof menus is the first step towards a smarter, more resilient setup.

Vibrant Banners for Unpredictable Outdoor Events

If you’ve ever organised an outdoor event in the UK, you know the weather is the one thing you can’t control. A sudden downpour can turn a beautiful banner into a soggy, unreadable mess in minutes. For markets, festivals, and sporting events, your signage has to be tough enough to handle sun, wind, and rain while still looking fantastic.

This is where weather-resistant PVC banners really shine. Printed with UV-cured inks that won’t fade in the sun, these flexible plastic sheets are built to last. They won’t tear in a gust of wind or run in the rain, keeping your branding bold and your message clear, no matter what the day throws at you.

Better yet, their flexibility means they can be rolled up, transported, and stored for the next event, making them a smart and sustainable investment.

High-Impact Stickers and Innovative Packaging

Beyond menus and banners, flexible plastic sheets are the unsung heroes of branding and product presentation. Think about a branded sticker on a laptop, a piece of equipment, or a company van. A vinyl or polypropylene sticker will stick around for years without peeling or fading, acting as a mini-billboard for your business.

In the world of retail, packaging is everything. It’s no surprise that the UK flexible plastic packaging market is thriving; in 2024, it made up a massive 55.62% of the total plastic packaging revenue in the country. This huge figure points to a clear need for packaging that’s both protective and looks great on the shelf.

Here are just a few ways businesses are using them:

- Custom Product Tags: Die-cut plastic tags feel far more premium than standard card.

- Clear PET Boxes: These let your product be the star, showing it off from every angle while keeping it protected.

- Durable Labels: For industrial products, chemical-resistant PP labels ensure critical information stays put.

From that first impression on the shelf to the lasting mark of a well-placed sticker, flexible plastics offer a polished and practical solution. They give you the creative freedom to design something memorable while delivering the performance you need to protect your products and promote your brand.

Picking the Perfect Sheet and Making It Last

With so many flexible plastic sheets to choose from, picking the right one is the first step to making sure your project is a success. It’s easier than it sounds. Just ask yourself a few simple questions, and the answers will point you straight to the perfect material for the job.

Once you’ve got it, a little bit of care goes a long way. Looking after your printed materials means you’ll get the most out of your investment, keeping them looking sharp and professional for years to come.

Guiding Questions for Your Project

Before you decide on a material, run through this quick checklist. It’ll help you find a plastic sheet that’s perfectly matched to its purpose and environment.

- Will it be used indoors or outdoors? If you’re creating outdoor banners or signs, you need a material that can stand up to the British weather. A tough, weather-resistant material like PVC is essential to fend off rain and stop UV rays from fading your design. For indoor displays, materials like PET or PP are fantastic choices.

- Does it need to be food-safe? For anything that will be used as food packaging, you have to use a food-grade plastic. PET is the go-to material here, as it’s non-toxic, stable, and widely approved for contact with food.

- What kind of look are you going for? Want your colours to be vibrant and really jump off the page? A gloss finish will give your design that eye-catching pop. If clear, easy reading is more important, a matt finish is the way to go, as it cuts down on glare.

Choosing the right flexible plastic sheet isn't about finding the 'best' material out there, but the best one for your specific job. Think about function, location, and the final look you want – those are your three most important guides.

Practical Care and Installation Tips

Now that you have the ideal product, a bit of proper handling will keep it in prime condition.

Cleaning Printed Materials: For things like wipe-clean menus or information panels, a soft, damp cloth with a bit of mild, non-abrasive cleaner is all you need. Steer clear of harsh chemical solvents or scouring pads, as they can easily scratch the print or dull the finish.

Applying Large Graphics: When you're putting up large vinyl stickers or window graphics, start by giving the surface a thorough clean. Use a squeegee to apply the graphic, working from the centre outwards. This simple trick pushes out any trapped air bubbles and gives you that smooth, professional finish.

Storing Your Banners: To stop your banners from getting creased between events, always roll them up with the printed graphic facing outwards. Pop them in a cool, dry place away from direct sunlight, and the colours will stay bright and fresh for next time.

Finally, a quick thought on the environment. Materials like PET are widely recyclable right here in the UK, making them a smarter choice for businesses looking to be a bit more sustainable.

Got Questions? We've Got Answers

Stepping into the world of flexible plastic sheets can bring up a few queries. Don't worry, it's completely normal. To help you out, we’ve put together straightforward answers to the questions we hear most often.

Can Flexible Plastic Sheets Be Recycled?

Yes, many of them can, but it’s all down to the specific material. Polyethylene Terephthalate (PET), for example, is one of the UK's most recycled plastics. You can spot it by looking for the number 1 in the little recycling triangle.

While some facilities also handle materials like Polypropylene (PP), it's always a good idea to check your local council's guidelines. That way, you know you're disposing of it correctly and helping support a more circular economy.

Are Printed Plastic Sheets Fully Waterproof?

Absolutely. This is one of their biggest selling points. Materials like PVC and polypropylene are naturally non-porous, which means water just beads up and rolls right off instead of soaking in.

It’s this quality that makes them a perfect fit for tough environments. Think of wipe-clean menus in a bustling restaurant, outdoor event signs braving the unpredictable British weather, or heavy-duty industrial labels in a factory.

What’s the Best File Format to Send for Printing?

To make sure your design looks as sharp in print as it does on your screen, a high-quality file is non-negotiable. We always recommend sending your artwork as a vector file, like a print-ready PDF or an Adobe Illustrator (AI) file.

For the best possible results, make sure your artwork is set to at least 300 DPI (dots per inch) and saved in the CMYK colour profile. This simple step prevents any unexpected colour shifts and ensures your final print is crisp, vibrant, and professional.

Ready to create durable, high-impact projects that last? Explore our full range of custom printing options at The Print Warehouse Ltd and find the perfect solution for your business. Start your order at https://theprintwarehouse.uk today.